SAP iMRO is a Solution Built on Component / Engine MRO and Aircraft AME but Extendable to:

- Trains

- Bridges / Tunnels

- Submarines

- Refineries

- Water Treatment Plants

SAP MRO Module

The MRO solution encapsulates any maintenance environment - typically one dealing with large assets that are subject to a high degree of regulation or complexity.

SAP Airline Solutions

SAP MRP is a key part of the SAP Airlines Solution and ultimately, part of the Aerospace & Defense (SAP for A&D) solution portfolio. It has been developed based on continuous input from SAP Airline Customers, through their membership in the SAP Airline User Group, which meets annually to discuss their SAP aviation maintenance requirements. It is part of the comprehensive SAP Solution developed to support the aerospace industry.

Follows SAP Development Guidelines

As an SAP-endorsed business solution, iMRO 6.9 is complementary to SAP software offerings, has been developed in accordance with SAP Development Guidelines , and provides additional choices and flexibility for businesses running SAP applications. This latest release is certified on the SAP ECC 6.0 Enhancement Pack 6 platform, including certification on SAP Business Suite on HANA.

Designed to Spur Innovation and Value Creation

Complex asset maintenance businesses rely on SAP to help them acquire, install, operate, overhaul, and ultimately to dispose of their complex, expensive assets. SAP technology provides end-to-end solutions that support each of these activities, within complete eco-system of manufacturers and MRO service providers.

Boosting Aftermarket Service Business

Integration with the SAP HANA platform, enterprise mobile apps, analytics solutions and SAP 3D Visual Enterprise Applications support manufacturing processes and help original equipment manufacturers (OEMs) transform their aftermarket services business. Aftermarket services typically offer higher profit margins than the sale of capital equipment and therefore OEMs are increasingly looking for ways to tap into this lucrative yet challenging market.

Enables Business Transformation Building Blocks

SAP iMRO Solution is a key enabling solution for business transformation. Through the use of fapid templated implementations MRO business transformation projects drive down project risk, increase project ROI and improve overall MRO business processes. Through the use of global template design and rollouts, customers can leverage the SAP S/4HANA platform and partner products to achieve entirely new, innovative, high-value process capabilities.

Provides 'Intelligent Maintenance' Capability Which Helps:

- Maximize Aircraft Flight Hours

- Minimize Ground and Hangar Time

- Reduce and Eliminate In-Service disruptions or delayed return to service due to maintenance faults

Supports Optimized Maintenance Core Practices

- Fixed scheduled (periodic and utilization based) maintenance

- Detailed Maintenance program developed along with Aircraft by Manufacturer to optimize asset life and flying time

- Tailored to fit with individual operations & corresponding aircraft configuration

- Failure Rate Pattern Monitoring -> Predictive Maintenance

- Condition Monitoring

- Integration to SCADA / ACARS

- Use of equipment redundancy for critical parts (i.e. HF radios)

- Use of Line Replaceable Units (LRUs)

- Maximized use of Minimum Equipment List (MMEL/MEL)

- Deferral of Maintenance without impacting Aircraft Operation

- Maintenance programs developed using two basic approaches:

- Process Oriented

- Task Oriented

Process Oriented

- Hard Time (HT)

- Parts with defined life limits (landing gear, etc.)

- Hard Life (mandated) and Soft Life (determined by Airline)

- Remove part and overhaul or discard

- Interval based on calendar time, landing cycles, flight hours, etc.

- On-Condition (OC)

- Parts with detectable wear-out periods (tires, brakes, control cables, etc.)

- Periodic inspection or test against standard

- Remove part and overhaul or discard

- Condition Monitoring (CM)

- Monitor failure rates, removals, etc.

- Operate until failure

- Require good records of unscheduled removals, maintenance log entries, pilot reports, etc.

Maintenance Practices Have Evolved

Task Oriented

- Predetermined maintenance tasks avoid In-Service failure

- Uses decision logic procedures

- Focus on consequence of failure at highest manageable level in aircraft systems

- 3 categories of Tasks

- Airframe Systems

- Structural Items

- Sources of deterioration:

- Environmental

- Accidental

- Fatigue

- Zonal Tasks

- Inspection of all systems, components in aircraft zone

Result : Original Equipment Manufacturer (OEM) MPD (Maintenance Planning Document)

- All Maintenance tasks details from Regulator and OEM

- Grouped by Letter check, hours, cycles, etc.

- Transit checks, 48 hour checks, Hourly limit checks, Operating cycle checks, Letter checks

- Also include details of access panels, man hours required, etc.

SAP Footprint in the Aviation Industry

- More than 100 Airlines Worldwide run SAP

- 25 % of those run SAP for MRO

- 9 of the top 15 Airlines for System traffic run SAP

- 7 out of top 10 most profitable airlines run SAP

- The top 5 Airlines for International traffic run SAP

- 14 of the 5 run SAP for MRO

- Independent MRO & OEM Aftermarket Services – Proven Solution

- 2006 Total Airframe Man-Hours By Corporate Entities

- 6 of the Top Ten Companies run SAP

- 2006 Third-Party Airframe Man-Hours By Corporate Entities

- 36 of the Top Ten Companies run SAP

- Over 40 Aviation Authorities, Airports and Air traffic entities run SAP

- 30 + years of Industry Experience with leading Industry user group for MRO

Core MRO Business Requirements

- Provide support for Regulatory requirements

- Preserves/Enhance Safety

- Deliver functionality to support business processes

- Deliver deep integration with Corporate functions

- Finance / Supply Chain / Human Capital Management

- Autonomy and flexibility to adapt solution to business changes

- Consultants trained with the know-how to implement and support the solution

- A solution that is continuously enhanced

- Up-to-date technology base

- Low Total Cost of Ownership

What you need in MRO Business Solution

A good MRO business solution coordinates all functions within the MRO organization to ensure an maximum efficiency and productivity, and maximum Aircraft Availability while staying within regulatory compliance guidelines.

It should provide support for:

- Developing a Business Plan

- Budget Constraints

- Reducing Costs

- Reduce Turnaround time

- Regulatory Compliance

SAP Aerospace & Defense Industry Solution Provides the Foundation for the MRO Solution

- MRO-M&E

- Airline Operations

- Manufacturing

- Defense

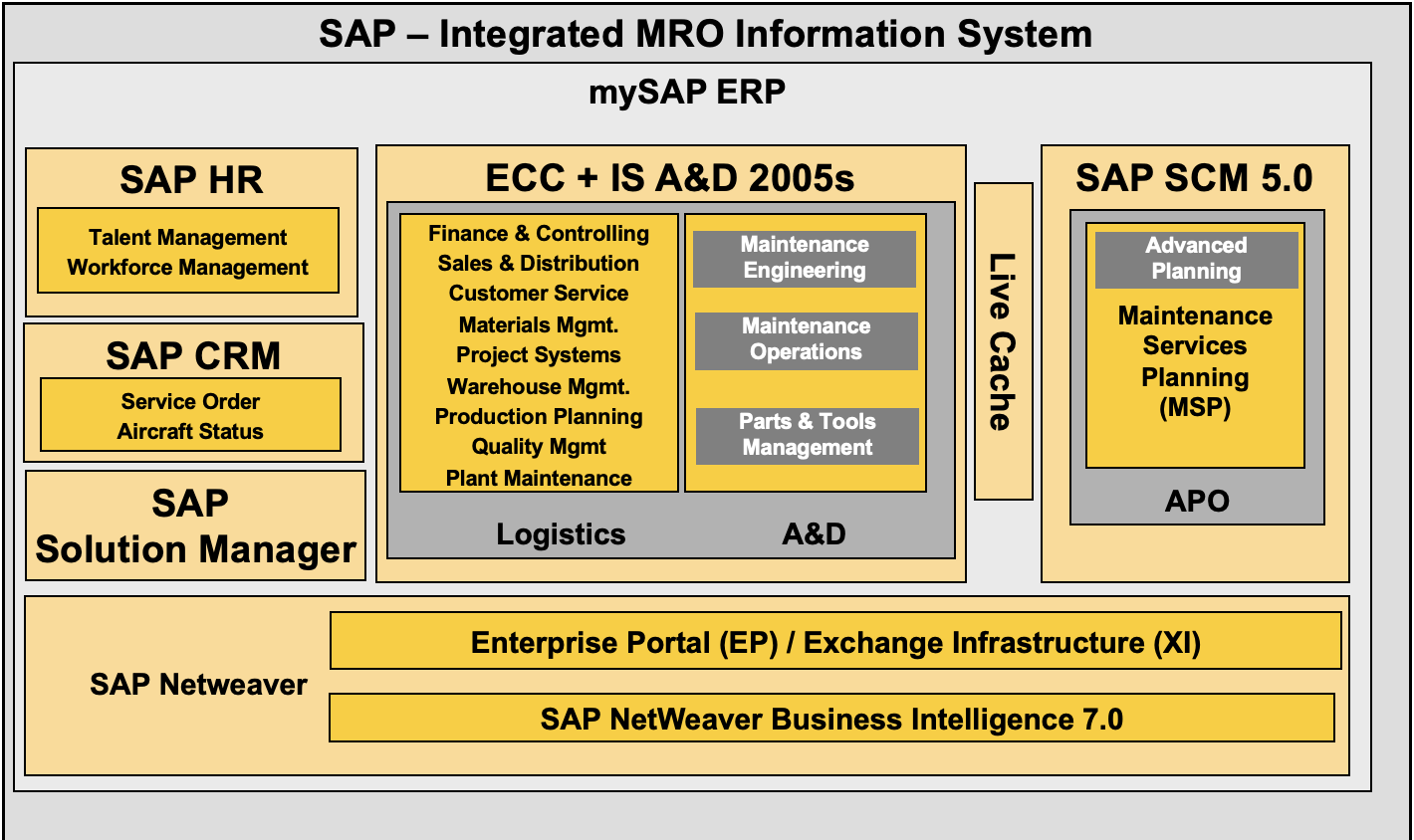

Typical Modules/Components for SAP MRO

Primary Modules

| Primary Modules |

Other Modules & Components |

| Plant Maintenance (Enterprise Asset Management EAM) |

Quality Management |

| Service Management |

Production - Process |

| Materials Management |

Warehouse Management (LE) |

| Sales & Distribution |

Document Management System (DMS) |

| Project System |

Maintenance Service Planning (Part of APO in SCM) |

| Finance & Controlling |

Business Intelligence |

| Human Resources (Mini Master) |

SAP HANA or SAP ECC (Certain Versions have different capabilities and limitations) |

| Industry Solution for A&D |

|

| Industry MRO |

|

iMRO is an SAP Endorsed Business Solution (SAP EBS) and add-on to SAP’s core product for MRO. It is built in SAP using NetWeaver

- Reduces custom development

- Reduces time, cost and risk to deploy SAP

- Reduces support costs (supported via SAP)

- Provides free software upgrades

- Is an investment in the future (3 yr. roadmap)

- Has been quality checked by SAP

iMRO Provides Extensive Usability Improvements and Enhancements

- Simple and intuitive user interface designs

-

Consistent, but context sensitive, layouts

-

Continuous status feedback

-

E.g. breadcrumb, highlight, mouse icon, tooltip etc.

-

Progress bar/message for >2 second tasks

-

Quality look and feel

Comes in Various Industry Flavors

Across the globe, railway customers have chosen to implement SAP solutions to run their core commercial systems of record, and they look to SAP to help extend their strategic investments. Through delivery of iMRO for Rail, used together with SAP EAM, rail customers have an even stronger set of solutions available for rail-assets management. iMRO and SAP EAM provide end-to-end support for the repair services business, from planning and engineering to work scoping and execution. Companies benefit through higher asset utilization and fewer un-forecasted flight schedule interruptions, fewer trains out-of-service and better overall profitability.